- Home Page

- Company Profile

- Our Products

- Contact Us

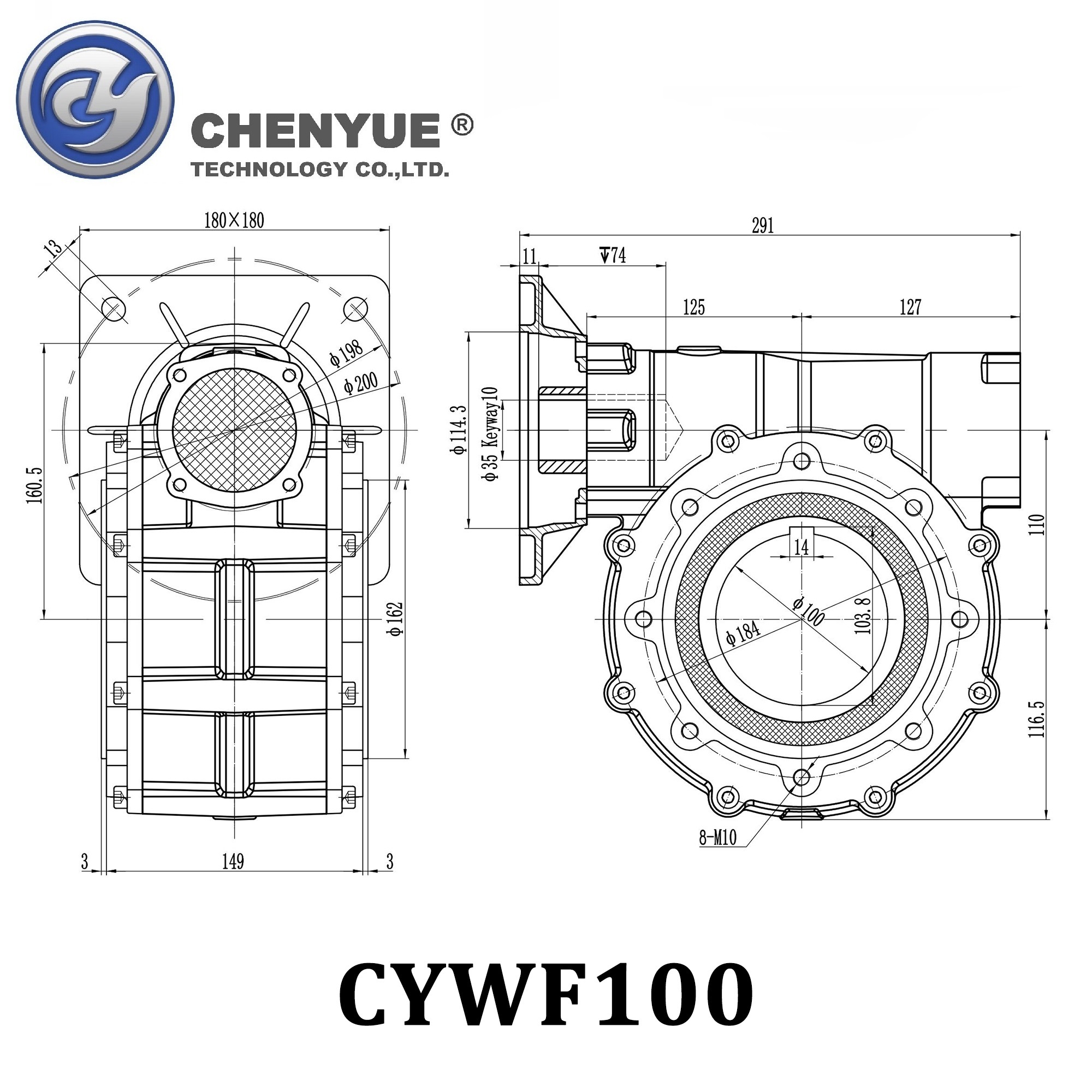

CHENYUE CYWF100 Worm Gearbox, Heavy Duty Worm Gear Reducer, 5:1 to 100:1 Speed Ratios, Fully Sealed Design, Lifetime No Refuel, Free Maintenance Industrial Gearbox

705.99 USD ($)/Piece

Product Details:

- Usage industrial

- Gear Type Worm Gears

- Material Other

- Processing Type Die Casting

- Size 30.5*29.5*38

- Height 38 Centimeter (cm)

- Gear Tooth Profile Other

- Click to View more

X

CHENYUE CYWF100 Worm Gearbox, Heavy Duty Worm Gear Reducer, 5:1 to 100:1 Speed Ratios, Fully Sealed Design, Lifetime No Refuel, Free Maintenance Industrial Gearbox Price And Quantity

- 705.99 USD ($)/Piece

- 1 Piece

CHENYUE CYWF100 Worm Gearbox, Heavy Duty Worm Gear Reducer, 5:1 to 100:1 Speed Ratios, Fully Sealed Design, Lifetime No Refuel, Free Maintenance Industrial Gearbox Product Specifications

- 200N.m-647N.m N-m

- Die Casting

- 30.5*29.5*38

- 0.75kW-7.5kW

- Other

- 24.5 Kilograms (kg)

- High

- 30.5 Centimeter (cm)

- 29.5 Centimeter (cm)

- Worm

- CYWF100 7.5 KW Worm Gearbox

- 38 Centimeter (cm)

- Worm Gears

- Other

- blue,green,gray

- industrial

CHENYUE CYWF100 Worm Gearbox, Heavy Duty Worm Gear Reducer, 5:1 to 100:1 Speed Ratios, Fully Sealed Design, Lifetime No Refuel, Free Maintenance Industrial Gearbox Trade Information

- 30000 Piece Per Month

- 3 Days

- Carton+Catalogue+Manual+PE Plastic Bag+QC Certificate+Anti-bump Filler+Desiccant+Engineering Plastic Tray

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

- CE/RoHS/IAF/CNAS/ISO9001/ISO45001/ISO14001

Product Description

Key features

Chenyue Jiangsu Technology Co Ltd IS CELEBRATING 30th ANNIVERSARY SALE 25 OFF

and other high end motors can be installed together with our worm Drive Gearboxes to be sold

WORM WHEEL ADOPTS HIGH QUALITY TIN Bronze long SERVICE LIFE AND MORE DURABILITY

Factory outlet provide video factory inspection

Speed ratio range from 51 to 1001

Input hole 35 mm

Output hole from 91 mm to 100 mm

Rated Input motor 075 kW-75 kW

Output Torque Range 200 N.m-647 N.m

Colors Blue or gray or according to customer required

Diecast aluminum alloy housing

Certification: RoHSCEIAFCNAS ISO90014500114001

Bipolar reducers available

Flange round or square

Delivery time 1-3 days for ready goodswe can deliver them within 2 days

Approximate gross weight 24.5 Kgpc

Key benefits

Maintenance free fully sealed no need fill oil for whole life

Good heat dissipation low temperature rise

Low noise smooth operation

Energy saving and high efficiency

Can be installed in any position and in all directions

Builtin fully synthetic lubricant no breather plug

Tip

The whole worm Gear Reducer is warranted for one year

The starting date of the warranty period is subject to the date of the

product invoice please present the invoice when repairing

Beyond the warranty period or does not belong to the free warranty

products the company maintenance center is still dedicated to serve you

Contact detail

If you need special customization or have requirements for delivery time please contact account manager

Advanced Worm Gear Technology

Utilizing premium worm gears, the CYWF100 Gearbox delivers high operational efficiency and reliable torque transmission. The fully sealed design ensures internal components are protected from contaminants, making it suitable for challenging industrial environments. Its die-cast construction improves strength and longevity, supporting smooth performance throughout its life cycle.

Optimized for Maintenance-Free Operation

Forget the hassle of frequent gearbox servicing. The CYWF100 is engineered for zero refueling and minimal upkeep, letting operators focus on productivity rather than repairs. The gearboxs internal system retains lubrication for life, keeping maintenance costs and downtime to a minimum, even in high-demand usage scenarios.

FAQs of CHENYUE Worm Gear Reducer CYWF100 speed ratio from 5:1 to 100:1 free maintenance, fully sealed, No need to refuel for life:

Q: How does the maintenance-free feature of the CHENYUE Worm Gearbox benefit industrial operations?

A: The maintenance-free feature means the gearbox is designed to operate without the need for periodic refueling or lubrication. This minimizes downtime and reduces maintenance costs, leading to increased operational efficiency in industrial settings.Q: What is the process behind the fully sealed construction of the CYWF100 Worm Gear Reducer?

A: The gearbox is manufactured using precise die casting, which ensures tight sealing and prevents oil leakage or contamination. This process guarantees the internal gears remain protected, extending the lifespan and reliability of the product.Q: Where can the CHENYUE CYWF100 Gearbox be used effectively?

A: This gearbox is ideal for a wide spectrum of industrial applications, including machinery, conveyor systems, and manufacturing equipment where dependable power transmission and high torque are essential.Q: What speed ratios are available for this worm gearbox, and how do they support different usage requirements?

A: The CYWF100 offers speed ratios from 5:1 up to 100:1, allowing users to select the optimal gear reduction for specific machinery requirements, whether they need higher precision or greater torque.Q: When should you consider using the CYWF100 Gearbox over alternative gearing arrangements?

A: This gearbox is best suited for scenarios that require robust torque output, high efficiency, and minimal maintenance, especially in environments where accessibility for servicing is limited.Q: How is the efficiency of the worm gear maintained over its lifespan?

A: The advanced sealing and die-casting techniques applied in manufacturing ensure no external contaminants enter the gearbox and the lubrication remains intact, guaranteeing high efficiency even after prolonged periods of use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free